8×10 metal garden shed suitable for most construction site condition

$1,708.10

8×10 metal garden shed

We are:

China’s Top Grade Manufacturer for Steel Structure Manufacturing

A-level for Professional Project Design of Steel Structure

National Grade 1 Speciality Contractor for Steel Structure

Standing director of China’s Construction and Metal Structure Association

Member of China’s Steel Structure Association and Shanghai Metal Structure Industry Association

Deputy chairman of Zhejiang Steel Structure Industry Association

FROM DESIGN, FABRICATION OF EVERY MEMBER TO INSTALLATION OF EVERY STEP, WE ALL PURSUE ACCURACY AND PERFECTION.

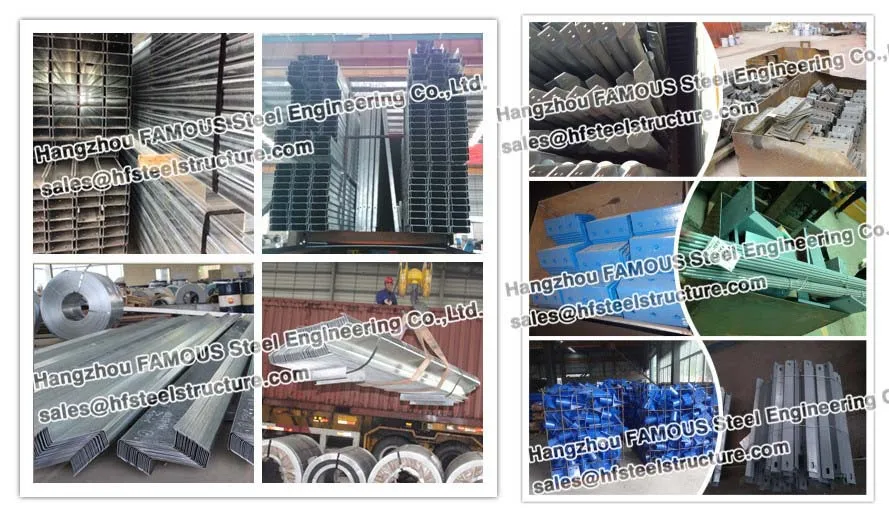

MAIN STEEL STRUCTURE

SECONDARY STEEL STRUCTURE

ROOF & WALL SYSTEMS, AND OTHER ACCESSORIES

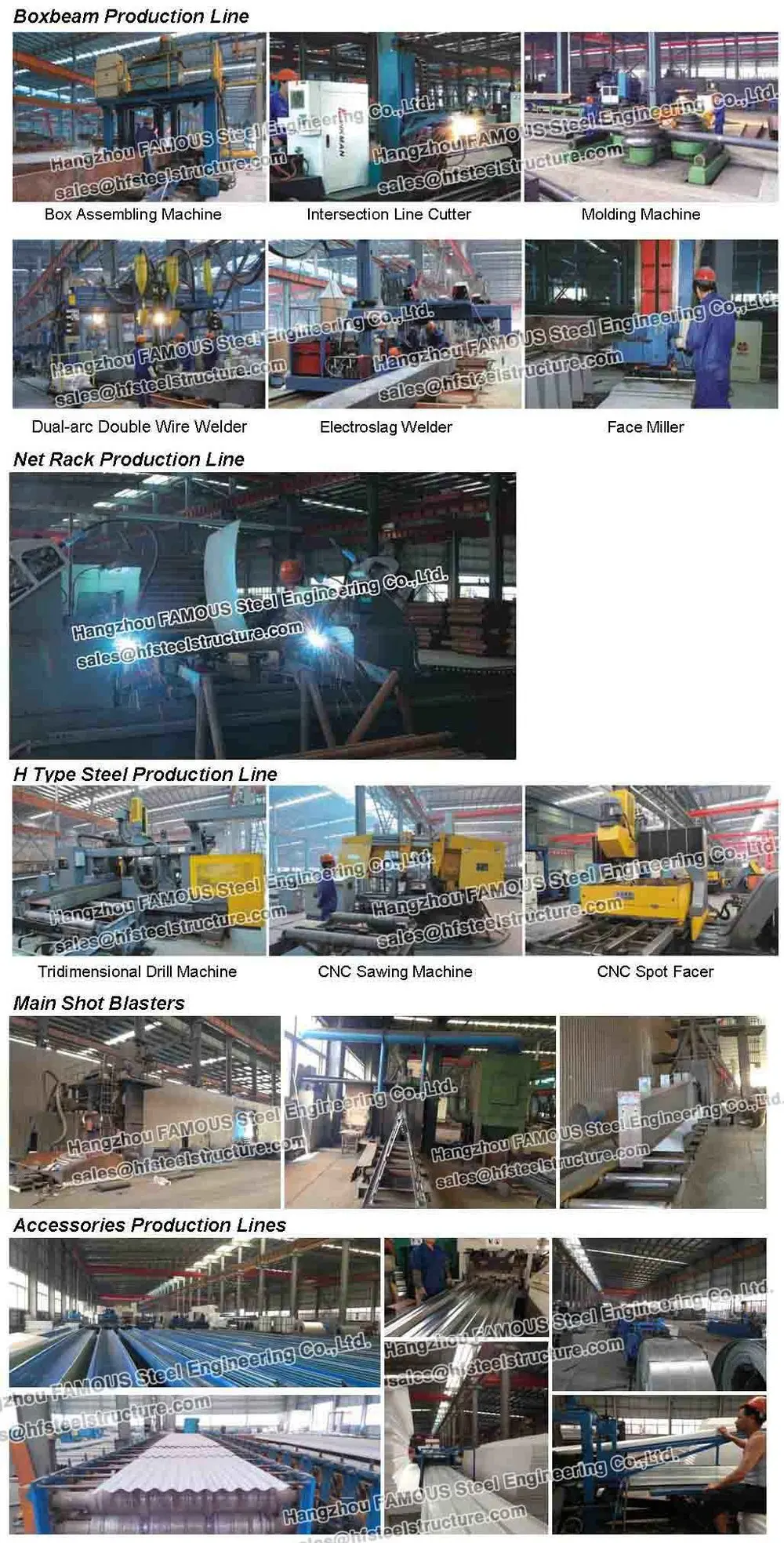

PRODUCTION LINES

Our group introduced from abroad the world-class professional production lines of steel structure, has the most advanced automatic H-beam production lines, pipe truss, box beam production lines, CNC hydraulic punching after-cutting C and Z types steel production lines, wall & roof panels, metal sandwich panel production line, etc., can complete all kinds of light steel, heavy steel, high-rise multi-spatial structure steel products processing tasks with high quality and efficiently.

PACKING & LOADING

We possess the unique most professional and best packaging in China presently – FRAMING PACKAGE, which perfectly protects the structural steel members from any impact damage during the transport. Of course, we also can package according to customer’s requirements. Generally, be loaded into 40/20GP, 40HQ, 40OT or Bulk carrier.

TECHNOLOGY R&D

Our group has over 1,200 employees of whom 206 are engineering technicians of all levels and all kinds and over 60 are state Grade 1, Grade 2 registered structure engineers, builders and architects.

The company has senior colleges and professional technology design organizations as the technology backup force and has established wide cooperation and R&D relations with such technology research institutes asZhejiang University, Northwestern Polytechnical University, Zhejiang Shuren University, etc.

DESIGN AND DETAILING

Standard: America Standard, Australia Standard, England Standard, China Standard, etc.

Software: SAP2000, Auto CAD, PKPM, RSTAB, PROE, MTS, Tekla Structures(Xsteel), 3D3S, Tarch, etc.

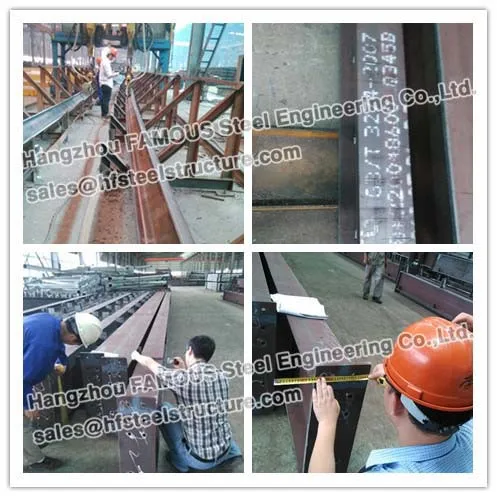

QUALITY MANAGEMENT

TODAY’S QUALITY, TOMORROW’S MARKET

Our group has established an advanced physical and chemical testing center of steel structure, owns the testing equipment such as electronic universal testing machine, electro-hydraulic servo universal testing machine, elemental analyzer, torsional testing machine, impact testing machine, ultrasonic flaw detector, blue ink coating thickness gauge, liquid crystal pendulum clock impactor, etc. In a large number of engineering practices, the company organized a high-quality construction team who grasp the leading construction technology, found scientific and strict construction management control process, has a control of the whole construction process to ensure the project quality.

Nondestructive Flaw Detection Competition of Welding Operators Technology Exchange

QUALITY INSPECTION BY BV, SGS, SKM, ETC.

Systematic Quality Process and Progress Control documentation: our fabrication process has been controlled by series of documentation and quality testing which are monitored and certificated by BV, SGS, SKM, JACOBES etc world-famous third party inspection organization.

CERTIFICATIONS

We have CE certificate, ISO9001 Quality Control Certificate, ISO14001 Environment-friendly Certificate etc systematic certificates to ensure our whole production progress controllable.

We also have systematic Quality Process and Progress Control documentation: Our fabrication process have been controlled by series of documentation and quality testing which are monitored and certificated by BV, SGS, SKM, JACOBES etc world-famous third party inspection organization.

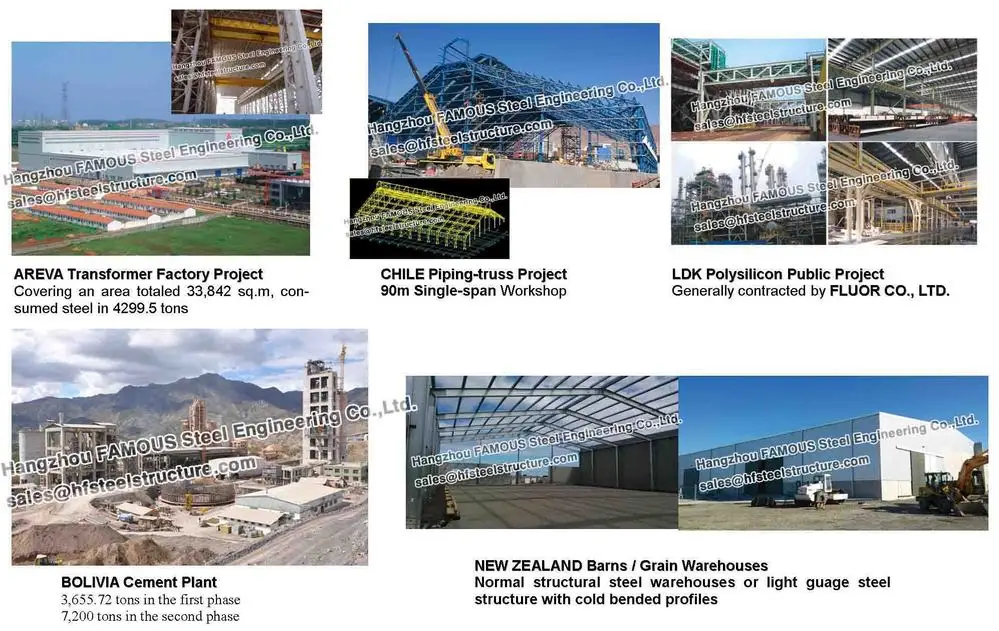

SOME OF OUR WORKSHOP/ WAREHOUSE PROJECTS

AREVA Transformer Factory Project:

Covering an area totaled 33,842 sq.m, the program consumed steel in 4299.5 tons, the column height is 31-33 m, and the inside is installed with the bunk bed traveling crane with the maximum hoisting capacity in 400 tons.

CHILE Piping-truss Workshops Project:

90m Single-span Workshops.

NEW ZEALAND Barns / Grain Warehouses:

light guage steel structure with cold bended profiles.

BOLIVIA Cement Plant:

Steel consumption: 3,655.72 tons in the first phase, 7,200 tons in the second phase.

LDK Polysilicon Public Project:

Was generally contracted by FLUOR CO., LTD., the total steel consumption volume for Phase I project reached over 30,000 tons and this program was in a high-rise steel structure of 4-7 floors.

CUSTOMERS’ VISITS

Welcome your visit! J